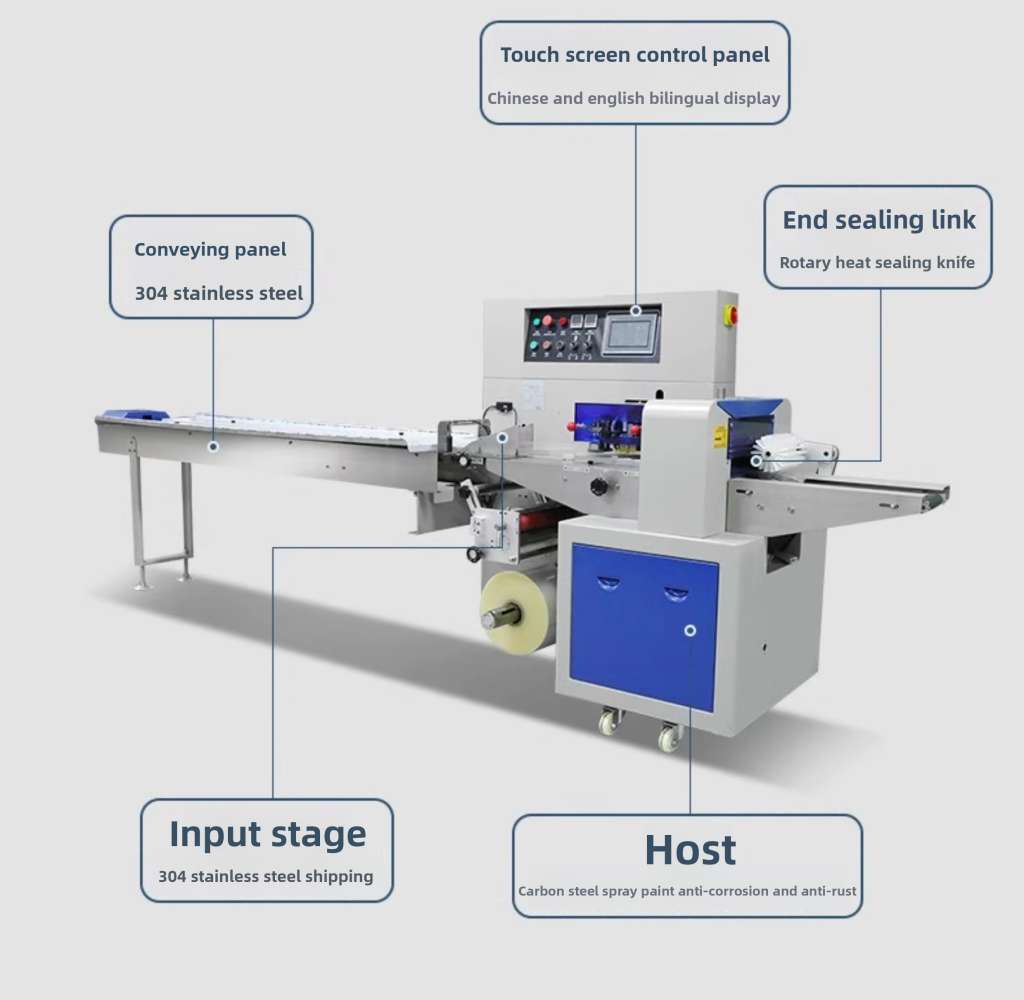

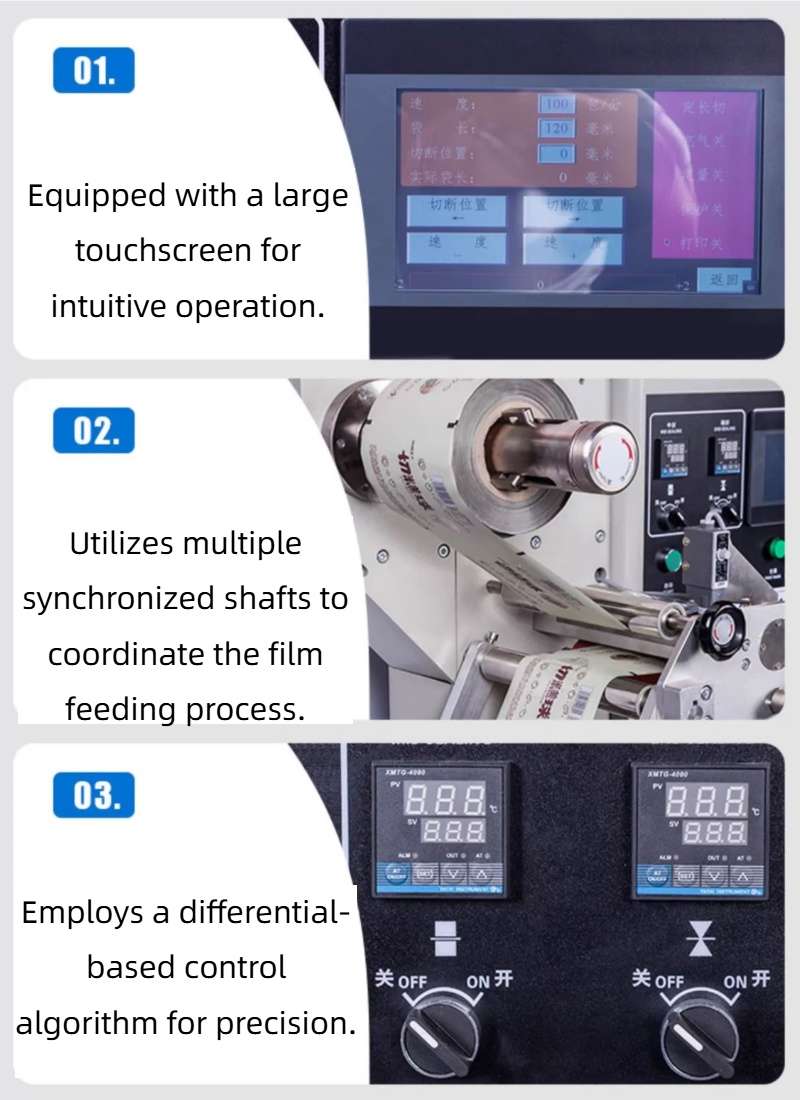

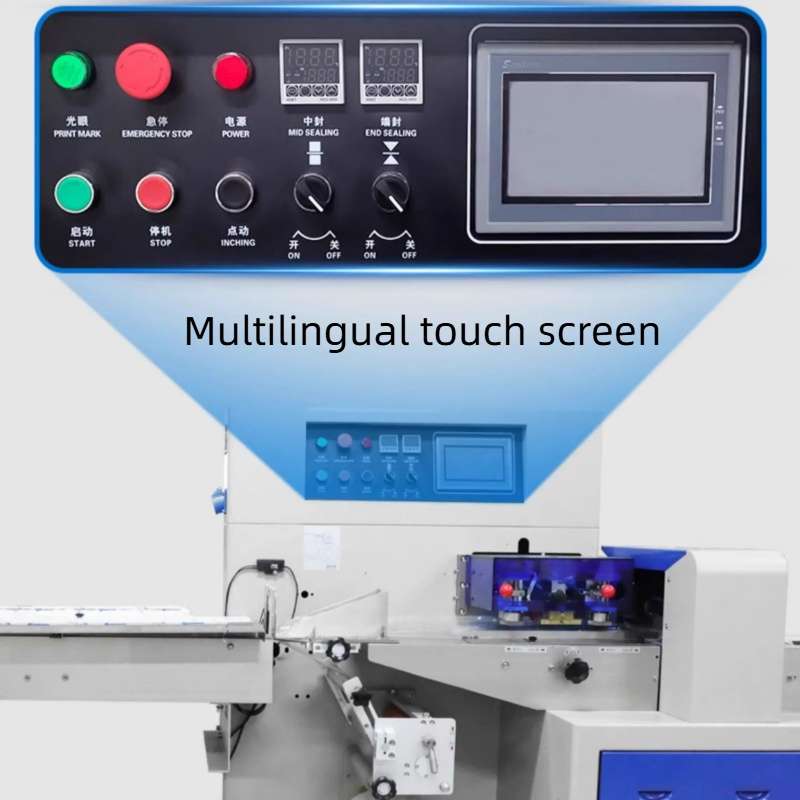

1. Smart Control Panel

-

Equipped with a large touchscreen for intuitive operation.

-

Allows for precise and convenient control of key parameters such as packaging speed and temperature.

2. Synchronized Film Roll Shaft

-

Utilizes multiple synchronized shafts to coordinate the film feeding process.

-

Accommodates a wider range of film materials.

-

Ensures smoother and more stable film unwinding.

3. Dual-Display Temperature Controller

-

Employs a differential-based control algorithm for precision.

-

Features external set point and valve position control functions.

-

Provides real-time temperature display for the packaging film.

Machine Specifications - ZY Series

| Specification / TYPE | ZY-250 | ZY-350 | ZY-450 | ZY-600 |

|---|---|---|---|---|

| Film Roll Diameter (mm) | 250 | 350 | 450 | 600 |

| Bag Making Length (mm) | B:65-190/120-280 D:90-220 |

D:90-220 | 130-450 | 120-500 |

| Bag Making Width (mm) | 30-110 | 50-160 | 50-180 | 100-280 |

| Product Height (mm) | B: MAX.40 D: MAX.55 |

B: MAX.40 D: MAX.60 |

MAX.75 | MAX.110 |

| Packaging Speed (bags/min) | 40-230 | 40-180 | 30-150 | 20-150 |

| Power (220V 50/60HZ) | 2.4 KW | 2.6 KW | 2.8 KW | 2.8 KW |

| Dimensions (mm) | 3770×670×1450 | 4020×770×1450 | 4020×820×1450 | 4020×920×1450 |

| Machine Weight (kg) | 500 | 580 | 650 | 680 |

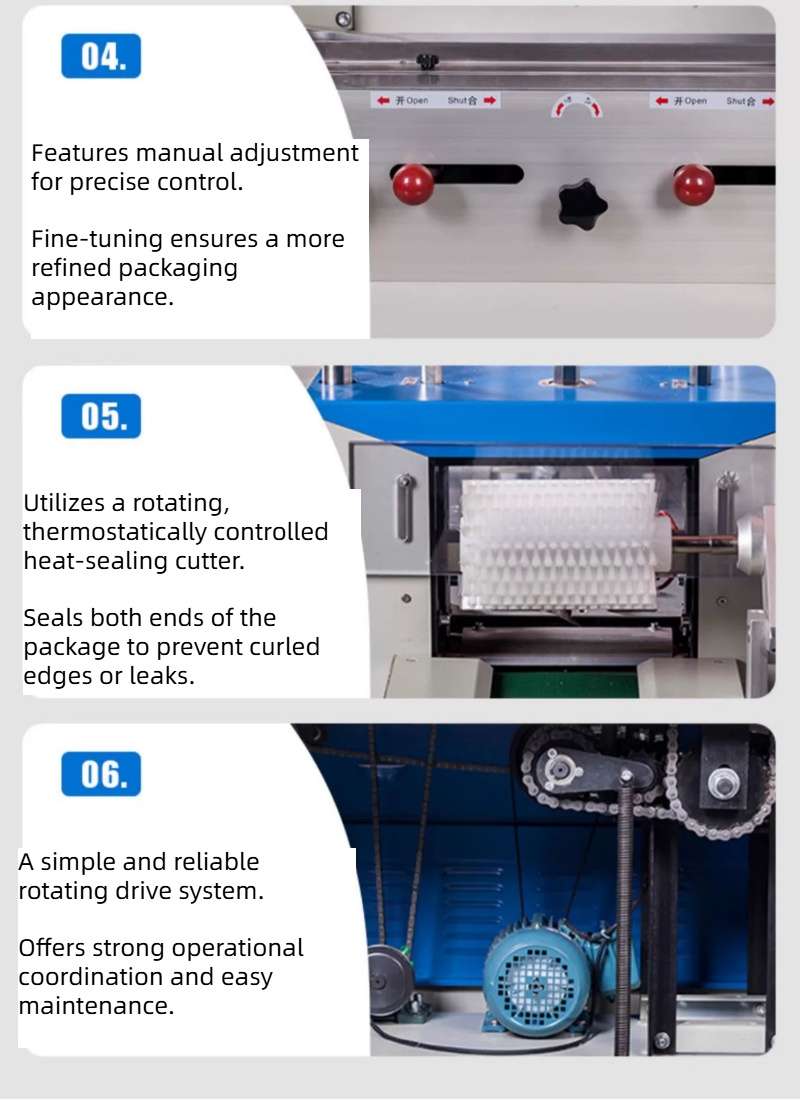

Additional Features

- Gas filling device can be added (nitrogen, oxygen, air, etc.)

Packaging Materials

- Compatible with single-side heat-sealable packaging films (such as OPP, CPP, OPP/PE composite, PET/PE composite, and other single-layer or composite packaging films)

Bag Shape

- Back seal packaging (customizable)

Longitudinal/Transverse Seal Pattern

- Mesh pattern packaging / Straight line, mesh pattern packaging

Note: Specifications are subject to change without prior notice.