300kg/hour Potato Peeling Washing Cutting 3-in-1 Machine | Professional Potato Processing Equipment

Specification

| Model | Capacity (Kg/h) | Size (mm) | Weight |

|---|---|---|---|

| IS-300 | 300 | 1030 × 550 × 1150 | 95kg |

| IS-500 | 500 | 1200 × 600 × 1050 | 120kg |

Product Overview

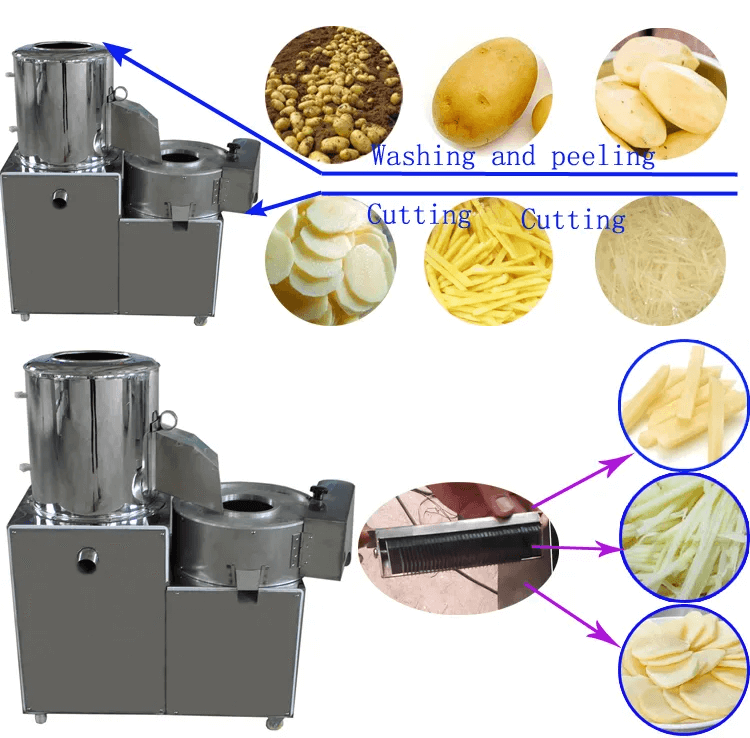

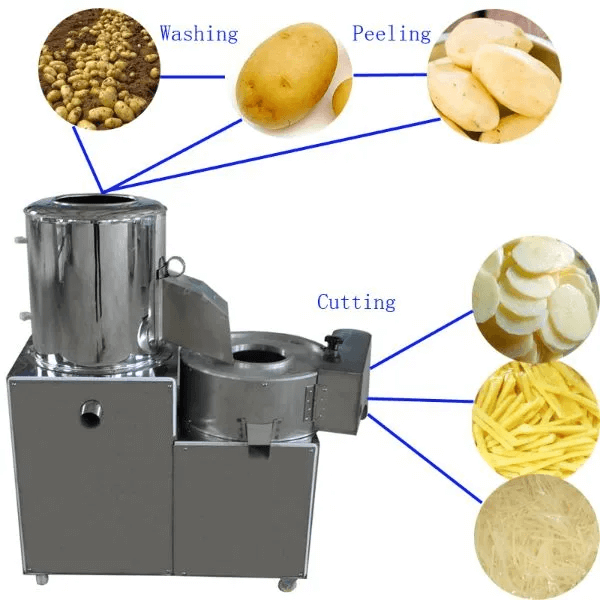

Industrial-grade 3-in-1 potato processing machine combining peeling, washing, and cutting fun

ctions in a single unit. Designed for high-volume production of potato fries, chips, and various sliced products. Perfect for food processing plants, snack manufacturers, and commercial kitchen operations.

ctions in a single unit. Designed for high-volume production of potato fries, chips, and various sliced products. Perfect for food processing plants, snack manufacturers, and commercial kitchen operations.

Key Features

- ✅ 3-in-1 Integrated Design: Peeling, washing, and cutting in one continuous process

- ✅ High Efficiency: Processes 300kg of potatoes per hour

- ✅ Multi-functional Cutting: Produces fries, chips, slices, and sticks

- ✅ Automatic Operation: Minimal manual intervention required

- ✅ Food-Grade Construction: 304 stainless steel contact parts

- ✅ Easy Maintenance: Modular design for simple cleaning and maintenance

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | IS-300 |

| Product Name | Commercial Vegetable Slicer |

| Power Rating | 1.5 KW |

| Production Capacity | 300 kg/H |

| Dimensions | 1030 × 550 × 1150 mm |

| Net Weight | 95 kg |

| HS Code | 8205510000 |

Applications

- French Fry Production: Uniform cutting for consistent quality

- Potato Chip Manufacturing: Precise slicing for perfect chips

- Vegetable Processing: Suitable for carrots, sweet potatoes, etc.

- Snack Food Production: Ideal for large-scale operations

- Restaurant Chains: High-volume potato preparation

Working Process

- Automatic Feeding: Continuous potato input system

- Efficient Peeling: Abrasive peeling with water spray

- Thorough Washing: Rotary brushing and water cleaning

- Precision Cutting: Adjustable thickness for different products

- Output Collection: Direct to processing or packaging line

Advantages

Quality Performance

- High Peeling Efficiency: Minimal product loss

- Uniform Cutting: Consistent size and shape

- Gentle Handling: Preserves product integrity

- Water Saving: Efficient water circulation system

Operational Benefits

- Labor Saving: Reduces manual work by 80%

- Space Efficient: Compact design saves floor space

- Easy to Operate: User-friendly control panel

- Low Maintenance: Durable construction with easy access parts

Quality Certification

- CE Certified

- ISO 9001:2015 Quality Management

- Food Safety Compliance

- 12-month warranty

Why Choose Our Machine?

- Professional Design: 15 years of food machinery experience

- Customizable Options: Tailored to your production needs

- After-sales Service: Global technical support network

- Competitive Pricing: Factory-direct prices with quality assurance

Contact us today for factory price and customization options! Professional food processing equipment manufacturer - Trusted by 1000+ clients worldwide