Liquid Filling Machine Specifications

Product Comparison Table

| Model | Filling Speed | Working Pressure | Power | Machine Weight | Dimensions |

|---|---|---|---|---|---|

| Single-Head Filling Type | 5-30 cups/min | 0.6-0.8 MPa | 1200W | 240kg | Customizable |

| Double-Head Filling Type | 8-40 cups/min | 0.6-0.8 MPa | 1350W | 300kg | Customizable |

Technical Specifications

Automatic Filling & Sealing Machine Specifications

Product Parameter Table

| Specification Category | Details |

|---|---|

| Model | KIS-1 / KIS-2 |

| Operating Voltage | 110V / 220V Dual Voltage Auto-Switching |

| Rated Power | 1.5kW |

| Machine Material | 304 Stainless Steel Frame |

| Production Capacity | Single-out mode: 600 cups/hour Dual-out mode: 1200 cups/hour |

| Dimensions | 1100×1100×1650mm |

| Working Air Pressure | 0.6-0.8MPa |

Technical Specifications

Key Features

- Dual Production Modes:

- Single-out: 600 cups/hour

- Dual-out: 1200 cups/hour

- Power Adaptability: Automatic 110V/220V voltage recognition

- Construction: Food-grade 304 stainless steel, compliant with hygiene standards

Physical Parameters

- Machine Dimensions: 1100mm(L)×1100mm(W)×1650mm(H)

- Operating Pressure: 0.6-0.8 Megapascal

- Power Consumption: 1.5 Kilowatt

Application Guide

Model Selection

- KIS-1 Model: Suitable for small batch production (600 cups/hour)

- KIS-2 Model: Ideal for medium/large scale production (1200 cups/hour)

Environmental Requirements

- Stable air supply (0.6-0.8MPa)

- Standard power connection (110V/220V)

- Minimum floor space: 1.21 square meters

Note: All specifications are based on standard testing conditions. Actual performance may vary depending on operating environment and product characteristics.

Performance Parameters

- Speed Range:

- Single-head: 5-30 cups/minute

- Double-head: 8-40 cups/minute

- Operating Pressure: 0.6-0.8 MPa (both models)

- Power Consumption:

- Single-head: 1200W

- Double-head: 1350W

Physical Specifications

- Weight:

- Single-head: 240kg

- Double-head: 300kg

- Dimensions: Customizable based on production line requirements

Features & Benefits

Single-Head Model

- Suitable for small to medium-scale production

- Lower power consumption

- Lighter weight for easier installation

- Ideal for limited space environments

Double-Head Model

- Higher production capacity

- Increased efficiency for large-scale operations

- Suitable for continuous production lines

- Better ROI for high-volume requirements

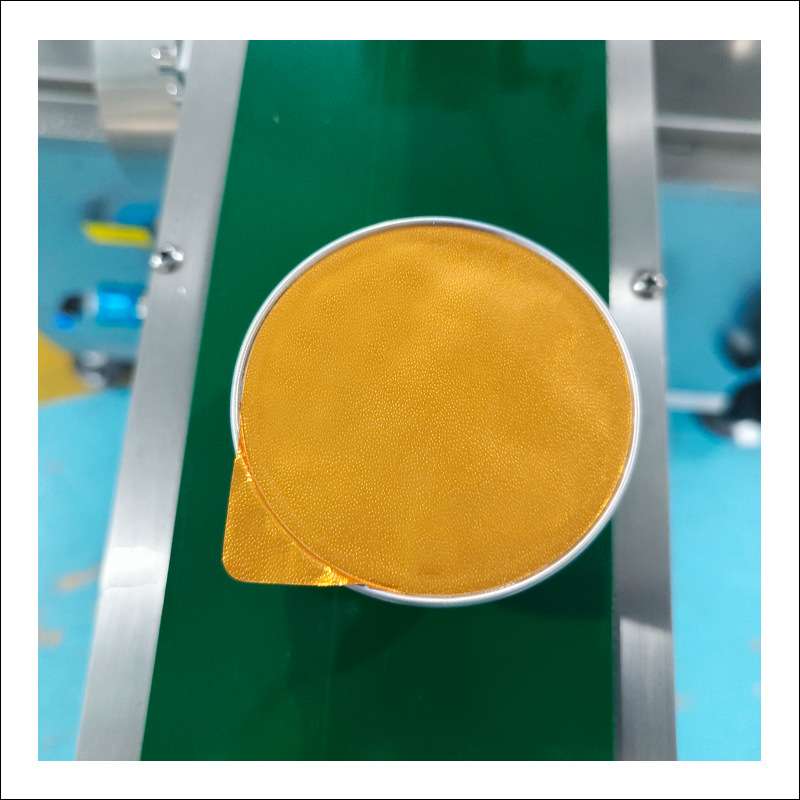

Applications

Recommended Use Cases

- Beverage Industry: Juice, milk, water filling

- Food Processing: Sauces, edible oils, liquid ingredients

- Chemical Industry: Liquid chemicals, detergents

- Pharmaceuticals: Liquid medicines, health products

Selection Guide

Choose Single-Head If:

- Production requirement: ≤ 30 cups/minute

- Limited factory space

- Budget constraints

- Intermittent production needs

Choose Double-Head If:

- Production requirement: 30-40 cups/minute

- Continuous operation needed

- Higher output targets

- Future expansion plans

Maintenance Requirements

- Regular pressure system checks

- Nozzle cleaning after each shift

- Monthly full system inspection

- Annual professional servicing

Note: Both models support custom configuration based on specific production requirements and container specifications.